A graphic lcd is a type of liquid crystal display that allows the presentation of images, symbols, and text in a pixel-based format. Unlike traditional character LCDs, which can only display fixed alphanumeric characters, a graphic LCD provides complete flexibility in designing custom visuals, icons, and messages. These displays have become an integral part of electronic devices used across industries such as medical equipment, industrial automation, automotive systems, and consumer electronics. They combine low power consumption, high reliability, and sharp contrast — making them one of the most versatile display technologies available today.

Understanding Graphic LCD Technology

A graphic LCD operates by controlling individual pixels arranged in a matrix format, typically expressed as resolution — for example, 128×64, 240×128, or 320×240 pixels. Each pixel can be turned on or off independently, allowing the display to form both text and graphical content. The display works on the principle of light modulation, where liquid crystal molecules align in response to an electric field, altering the passage of light through polarizing filters.

These displays usually use a backlight, often LED-based, for illumination, and can be either monochrome (black and white) or multicolor, depending on design requirements. They can also be classified as reflective, transmissive, or transflective, depending on how they utilize ambient or internal light sources. Reflective displays are ideal for sunlight-readable applications, while transmissive types work best in indoor environments with consistent lighting.

The control of a graphic LCD is managed through a display controller IC (such as KS0108 or ST7920), which interfaces with a microcontroller via communication protocols like SPI, I2C, or parallel connections. This allows users to draw custom graphics, fonts, and animations with precise control.

Key Features and Advantages of Graphic LCDs

The graphic lcd offers several key advantages that make it an ideal choice for a wide range of electronic applications:

- Design Flexibility: Because each pixel is addressable, designers can display complex visuals, logos, and dynamic data without being restricted to predefined character sets.

- Energy Efficiency: Graphic LCDs consume minimal power, making them suitable for battery-operated or portable devices.

- Durability and Stability: With solid-state construction and low heat generation, these displays offer a long operational lifespan.

- Wide Viewing Angles: Advanced LCD technologies such as FSTN (Film Super Twisted Nematic) and STN (Super Twisted Nematic) enhance readability across different angles.

- Cost-Effectiveness: Compared to OLED or TFT displays, graphic LCDs provide excellent performance at a lower cost, especially for monochrome applications.

Additionally, these displays can operate in a wide temperature range, typically from -20°C to +70°C, ensuring reliability in both industrial and outdoor environments.

Applications Across Industries

Graphic LCDs are widely used in numerous fields due to their adaptability and precision. In industrial automation, they serve as control panels for machinery, providing clear visual feedback and data monitoring. In medical devices, graphic LCDs are used in diagnostic instruments, infusion pumps, and handheld monitoring equipment for displaying readings and status indicators.

In the automotive sector, they appear in dashboards, climate control systems, and infotainment displays. Their ability to present both graphical and numerical data makes them ideal for real-time monitoring. Consumer electronics, such as coffee machines, printers, and measuring instruments, also use graphic LCDs for user-friendly interfaces.

Types of Graphic LCDs

There are several types of graphic LCDs available, depending on technology and application requirements:

- STN (Super Twisted Nematic): Offers good contrast and is widely used in standard applications.

- FSTN (Film Super Twisted Nematic): Provides better contrast and viewing angles than STN displays.

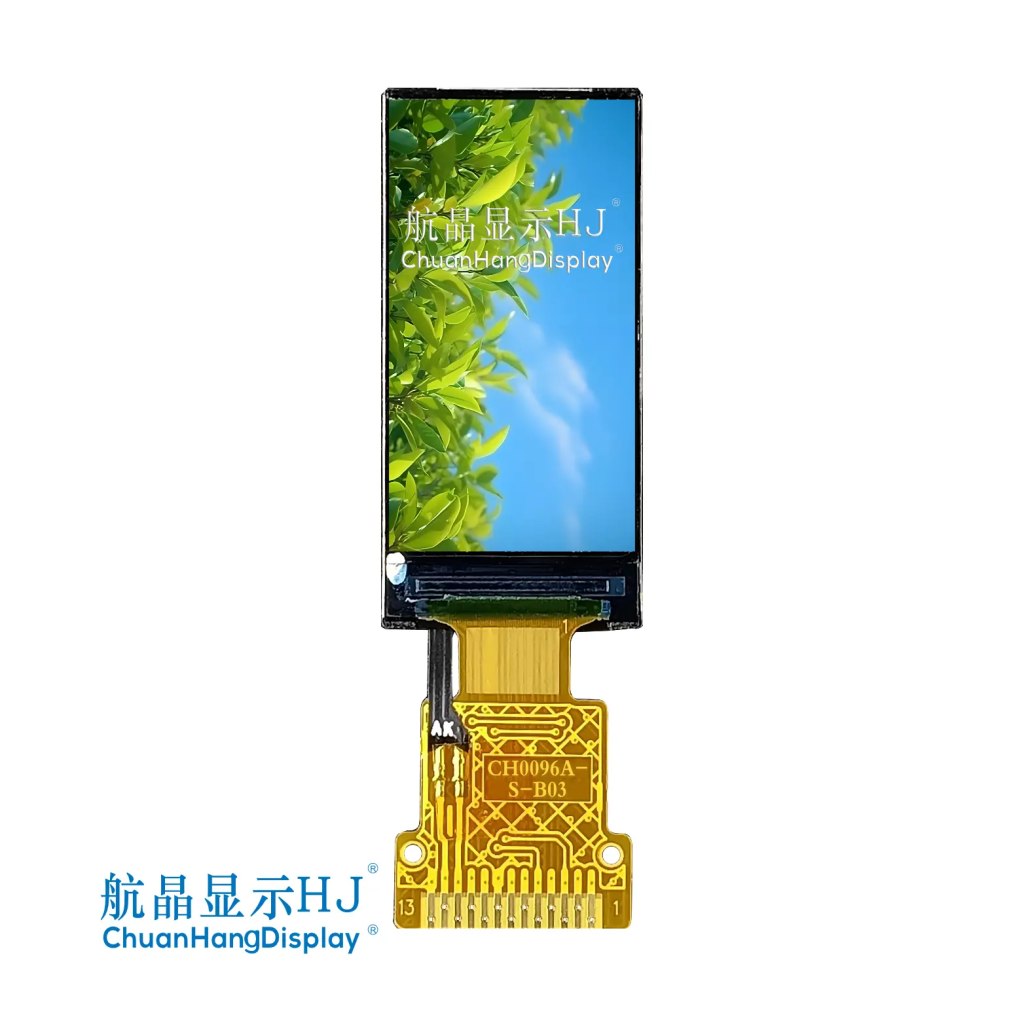

- TFT (Thin Film Transistor): A color-capable version of graphic LCD technology with high resolution and refresh rate.

- COG (Chip on Glass): Integrates the driver IC directly onto the glass, making the module thinner and more compact.

Each type is available in different resolutions, sizes, and backlight configurations, allowing designers to select the ideal display for their specific product.

Integration and Customization

Graphic LCDs can be customized in terms of resolution, display mode (positive or negative), backlight color, and interface type. Manufacturers often offer tailored solutions with branding, unique layouts, and backlight brightness adjustments. Integration with touch panels is also becoming more common, transforming standard displays into interactive interfaces.

The use of standard development libraries makes programming and interfacing with microcontrollers simple. With platforms such as Arduino, STM32, or Raspberry Pi, developers can easily program custom images, text, and animations.

Conclusion

A graphic LCD is a powerful and adaptable display solution that bridges the gap between simple segment displays and complex color TFT screens. It offers an optimal balance of cost, performance, and energy efficiency, making it a popular choice across multiple industries. With advancements in resolution, readability, and customization, graphic LCDs continue to evolve — providing reliable visual communication in an increasingly digital world. Whether used in industrial machinery, automotive systems, or consumer electronics, the graphic LCD remains an essential technology for clear, efficient, and versatile information display.