In today’s competitive printing and manufacturing landscape, efficiency, consistency, and durability are non-negotiable. Businesses handling large-scale production require equipment that can operate continuously without compromising quality. This is where an industrial heat press becomes an essential investment. Designed for heavy workloads and professional environments, industrial heat press machines deliver precision, speed, and reliability for demanding applications.

From garment manufacturing to promotional product printing, industrial heat presses are trusted tools that support scalable business growth.

What Is an Industrial Heat Press?

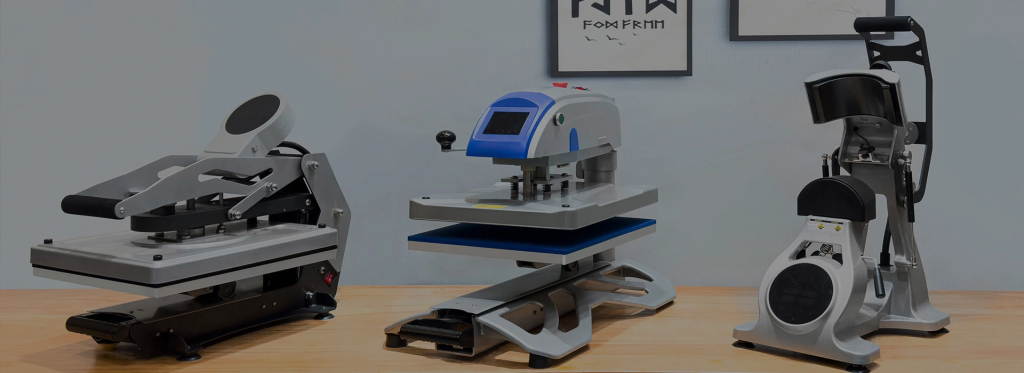

An industrial heat press is a heavy-duty machine engineered for high-volume heat transfer applications. Unlike standard or hobby-level presses, industrial models are built with reinforced frames, advanced heating systems, and powerful pressure mechanisms. These machines are capable of maintaining consistent temperature and pressure over extended production cycles.

An industrial heat press is commonly used in factories, commercial print shops, and large customization facilities where output consistency and operational uptime are critical.

Key Features of an Industrial Heat Press

Industrial heat press machines are defined by advanced features that enhance performance and productivity. One of the most important features is uniform heat distribution across the platen. This ensures even transfers, reducing errors such as scorching, peeling, or incomplete adhesion.

Another essential feature is precise digital control. Modern industrial presses allow operators to set exact temperature, pressure, and time parameters, ensuring repeatable results across thousands of units. High-pressure capacity also enables printing on thicker materials and specialty substrates.

A well-designed industrial heat press combines automation, accuracy, and strength to support uninterrupted workflows.

Applications Across Industries

Industrial heat presses are used across a wide range of industries. In apparel manufacturing, they are essential for applying heat transfer vinyl, sublimation prints, and screen-printed transfers. Promotional product companies rely on them for printing logos and designs on bags, uniforms, and accessories.

They are also widely used in industrial labeling, signage production, and technical fabric processing. The versatility of an industrial heat press allows businesses to expand their service offerings without investing in multiple machines.

Built for Durability and Long-Term Use

One of the defining advantages of industrial heat press machines is durability. These machines are constructed using industrial-grade steel frames, high-quality heating elements, and reinforced pressure systems. This construction ensures they can withstand constant use in demanding environments.

A reliable industrial heat press minimizes downtime, reduces maintenance costs, and delivers consistent output year after year. This long-term reliability makes it a cost-effective solution for businesses focused on scalability and operational efficiency.

Efficiency and Production Speed

Speed is a critical factor in industrial production. Industrial heat presses are designed to heat up quickly, recover temperature rapidly between cycles, and operate efficiently during long shifts. Some models include automated or pneumatic systems that further increase throughput while reducing operator fatigue.

With an industrial heat press, businesses can meet tight deadlines, handle bulk orders, and maintain quality standards even under pressure. This efficiency directly translates into higher profitability and customer satisfaction.

Safety and Operator Control

Despite their power, industrial heat presses prioritize operator safety. Features such as emergency stop buttons, heat-resistant handles, and automated shut-off systems help prevent accidents. Ergonomic designs and intuitive control panels also improve usability and reduce training time.

A user-focused industrial heat press ensures that operators can work safely and confidently, even in fast-paced production environments.

Choosing the Right Industrial Heat Press Supplier

Selecting the right supplier is just as important as choosing the machine itself. A reputable supplier offers tested equipment, technical support, and reliable after-sales service. They also understand industry requirements and continuously improve product designs based on real-world usage.

If you’re looking for a dependable industrial heat press, working with an experienced manufacturer ensures access to advanced technology, robust construction, and solutions tailored for professional production needs.

Final Thoughts

An industrial heat press is more than just a printing tool—it is a production powerhouse. Designed for accuracy, durability, and efficiency, it supports businesses that demand high output without sacrificing quality.

Whether you operate a large print shop, manufacturing facility, or customization business, investing in a high-quality industrial heat press positions you for long-term success. With the right machine and a trusted supplier, businesses can achieve consistent results, meet growing demand, and stay competitive in an evolving market.